Water is a precious resource within the business of resources.

It’s common knowledge that mine sites are usually remote. Often they are also located in dry places far from any usable natural sources of water. In this case, water use has a substantial financial metric associated with it.

Dust events can shut down an operation and also be costly. During these events, water tanks must be ready for immediate deployment to limit any stoppage time.

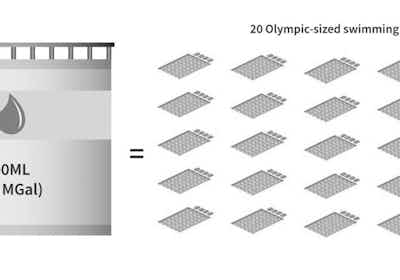

To paint the picture, a large open pit coal mining operation can use up to 50 ML (11 MGal) of water in 2-3 minutes during a dust event. That’s the equivalent of 20 Olympic-sized swimming pools.

Most open pit coal mining operations have dust control plans that guide their operation teams on how much water should be used - but is this actually effective?

Although it’s good to have an expectation of a difference between the dust control plan and the actual execution, it’s important to have a good understanding of how effective the plan is and therefore to know how well it is being implemented.

Using data to validate a dust control plan

Operations teams should always ask themselves: ‘What is the situation in this current moment?’

Analysing water utilisation data in real-time can provide a very good indicator of how well the dust control plan is followed. This can be done by capturing water usage and correlating it with the expected water usage.

What we’ve found at Envirosuite is that just having a sensor that provides water usage may not actually be sufficient coverage. This is simply because of the hard truth that, every week and every day, operations face different challenges from weather events.

It’s far too late to look at water data one month later, or even a week later. This adds to the frustration of the planning and operations team by creating the feeling that they are constantly chasing their own tails.

Boosting efficiency of trucks stopping at pumps

Open pit coal mines also have an issue with water trucks stopping for far too long at water pumps. Trucks can stop at 12-15 minutes per pump.

Some coal mining operations make up the largest mining operations in the world. It doesn’t take long to imagine the size of the logistical challenge this poses the operations team.

By analysing sensors providing pump valve and flow data in real-time, it’s easy to get a view of the amount of water used at each water pump around the site. This makes it easier to identify if a pump is not working correctly or if it needs to be fixed to maximise water usage.

An example of Envirosuite technology visualising pump valve and flow data in real-time

Data creates harmony between Operations and Environmental teams

Environmental data can become a powerful optimisation tool for routine operations. By incorporating a real-time monitoring system as a window into a mine site’s inefficiencies and as a way of validating current dust control strategies, there is a large potential to bring harmony between operations and environmental teams.

A system that includes alarms and regular reporting on routine processes can be the key for planning to be informed on time and planning to provide responses based on what is happening. This allows for any team to be more adaptable to unpredictable weather events, limit critical dust events and operate more efficiently.